- In domo

- Productio

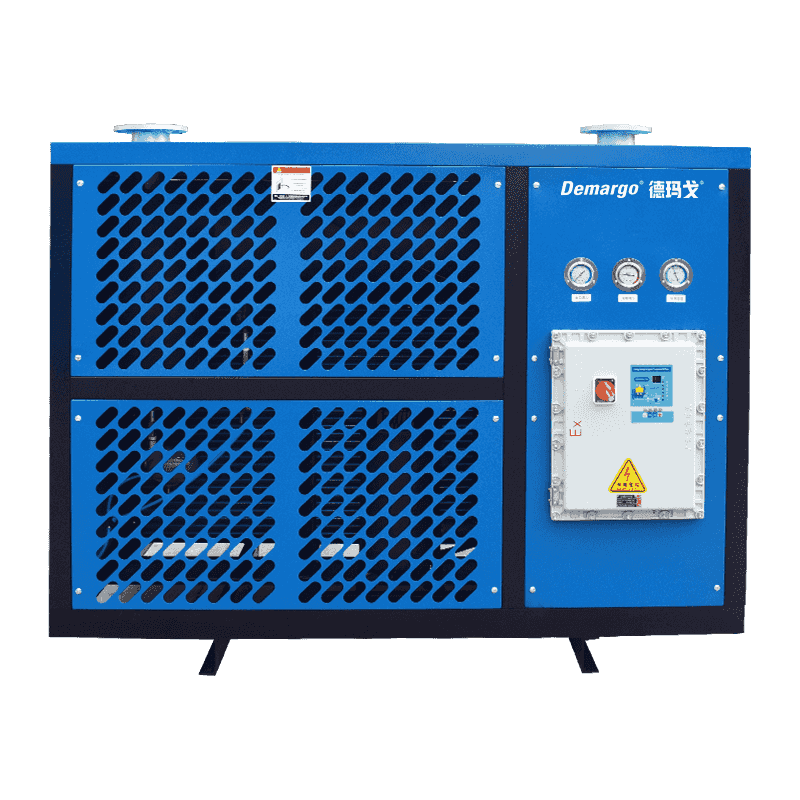

- Frigidus Dryer

- ADSORPTIONPTIONPTIONPTIONPTION Dryer (Duplex Tower Type)

- Combined Minimum Ros Point compressa Aeris Dryer

- Compressionem calidum regenerationem adsorption dryer

- Micro Aeris consummatio, nulla aer consummatio inspiratione calidum regenerationem dryer

- Module / Finge Core Dryer

- Special Gas Dryer

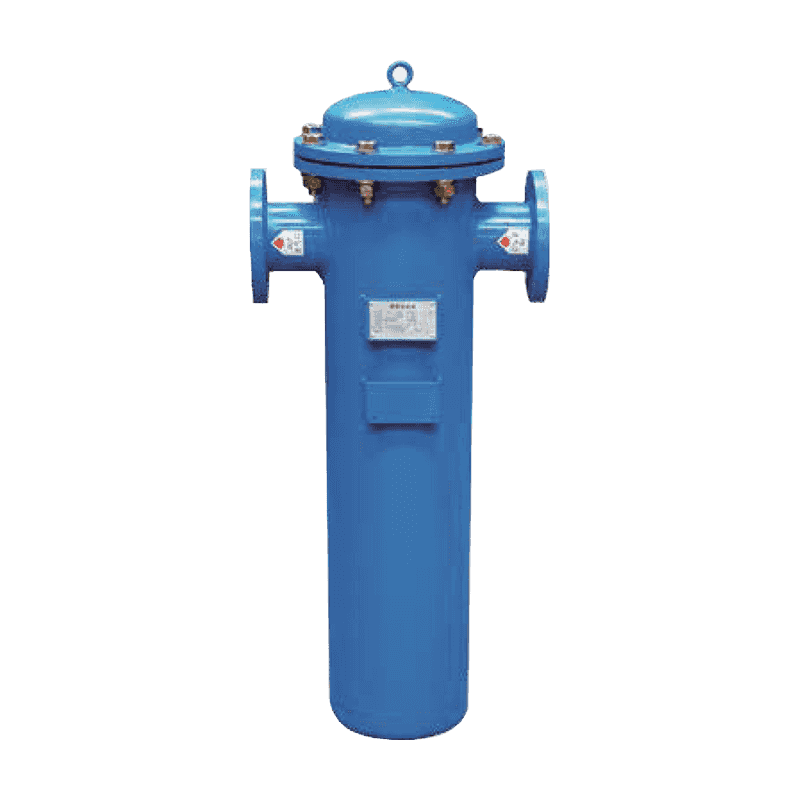

- Compressi aeris filter

- Aliquam Steel compressa Aeris Filter

- Maximum efficientiam oleum Aufero

- Oil Collector / Condensate / Condensate Treatment SEPARATOR

- Oleum aqua separator

- INCILE Type

- CREPITUS Dryer,

- De

- Applicatio

- Casus

- Ministerium

- Nuntium

- Contactus

Inquire nunc