Demargo (Shanghai) Energy Saving Technology Co., Ltd. Active participat in industria aeris compressi eamque progressionem promovet. In fabricatione et productione apparatuum purificationis aeris compressi specializatur. Hactenus, plures patentes productorum, certificationes QS, et certificationem systematis qualitatis ISO9001 superavit. Societates nationales technologiae altae et specialisatas adepta est, usoribus producta summae qualitatis et officia ante-venditionem et post-venditionem perfectissima praebens.

Demargo (Shanghai) Energy Saving Technology Co., Ltd. est

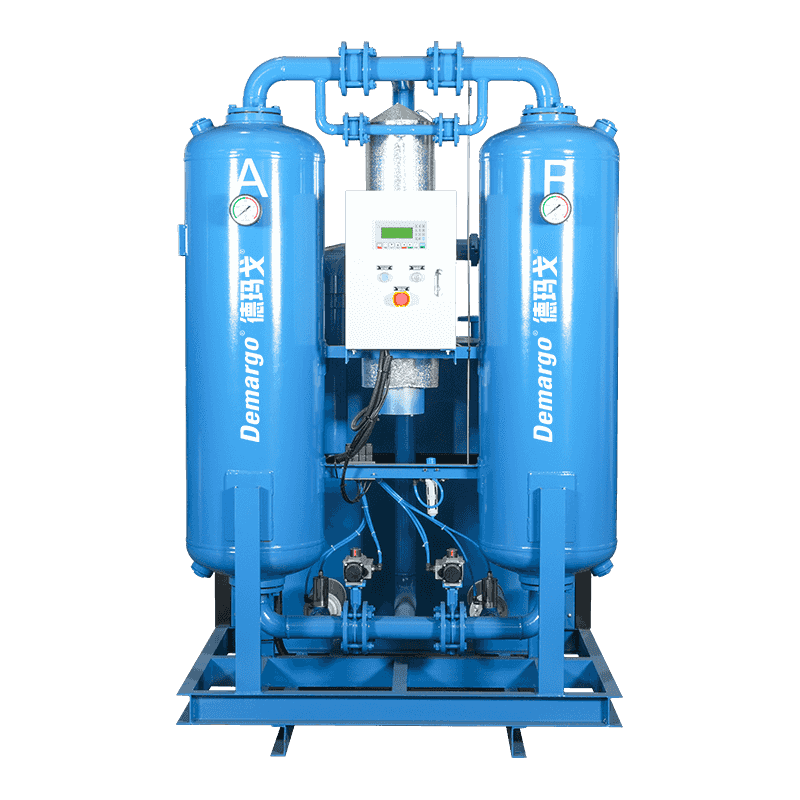

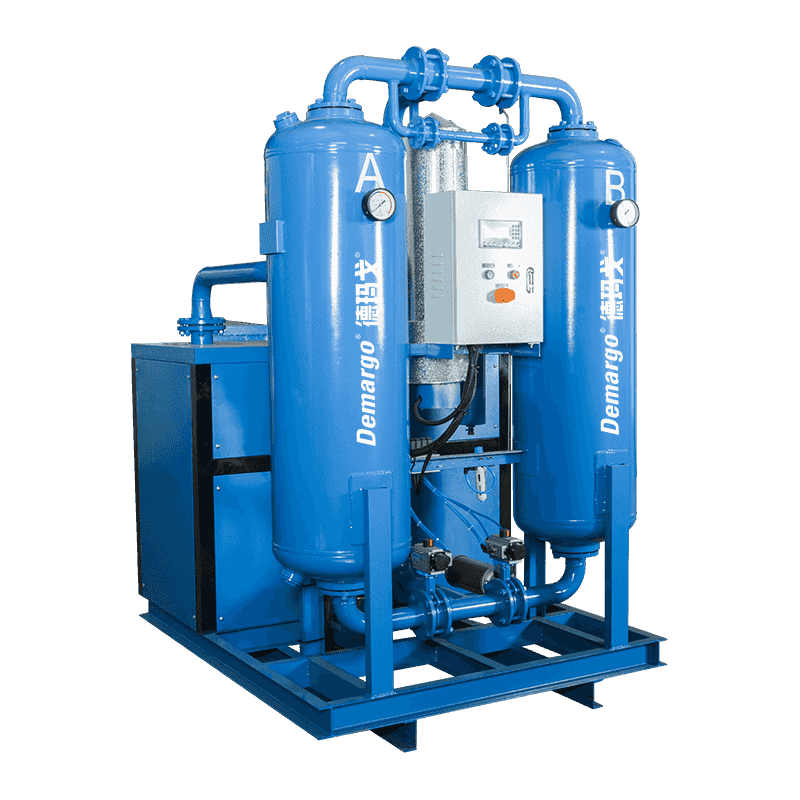

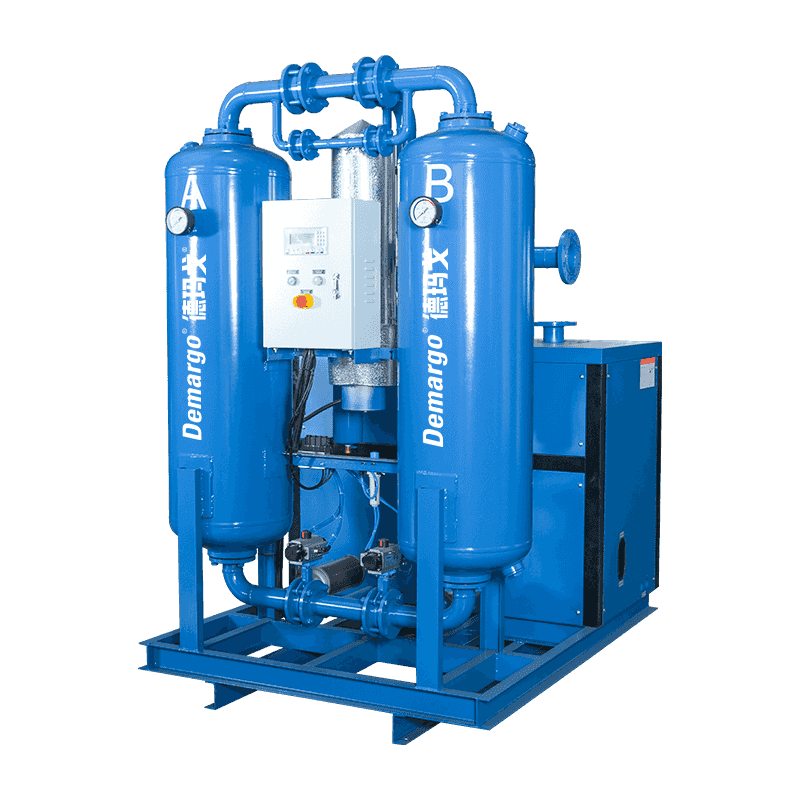

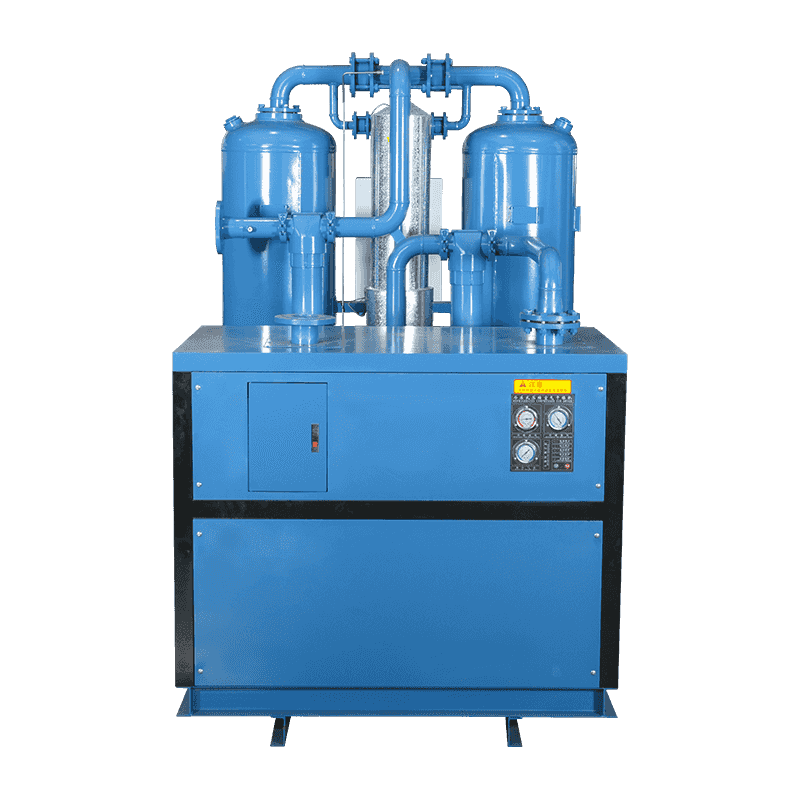

Venditor Sinensis Microheat combined compressi aer dryer Fabricatores et

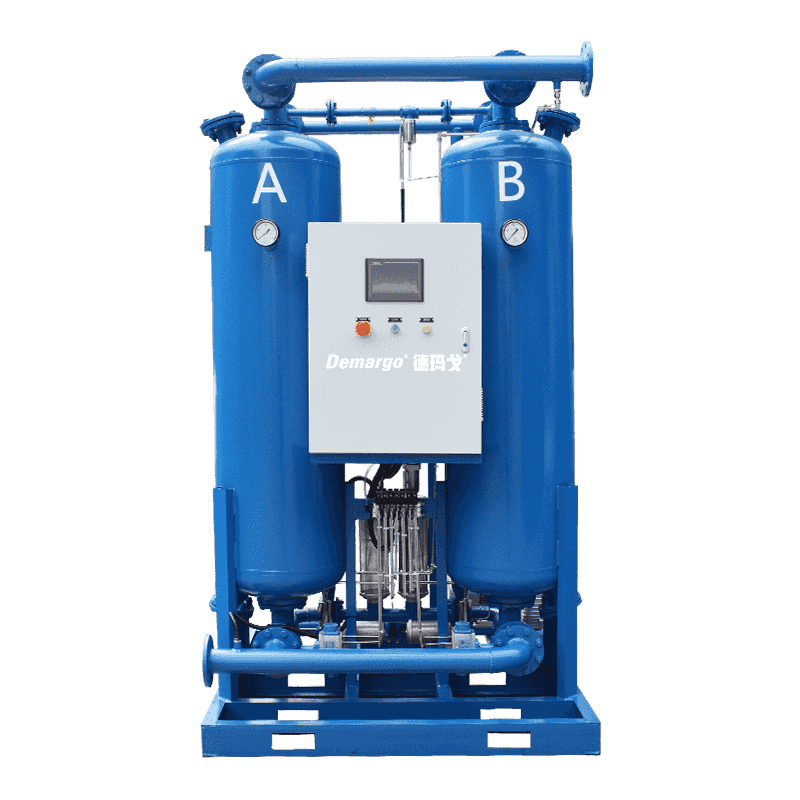

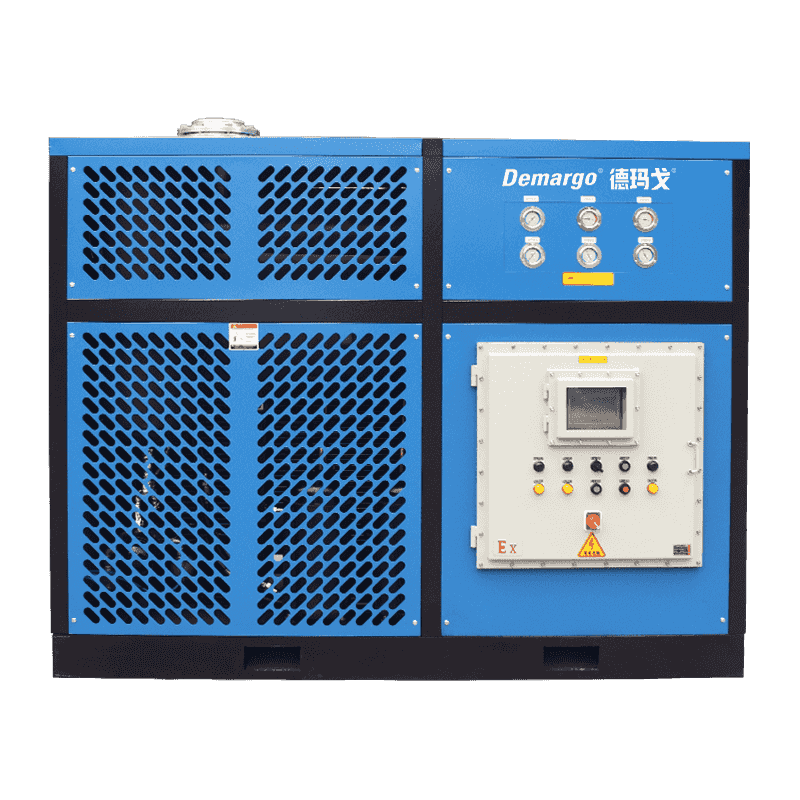

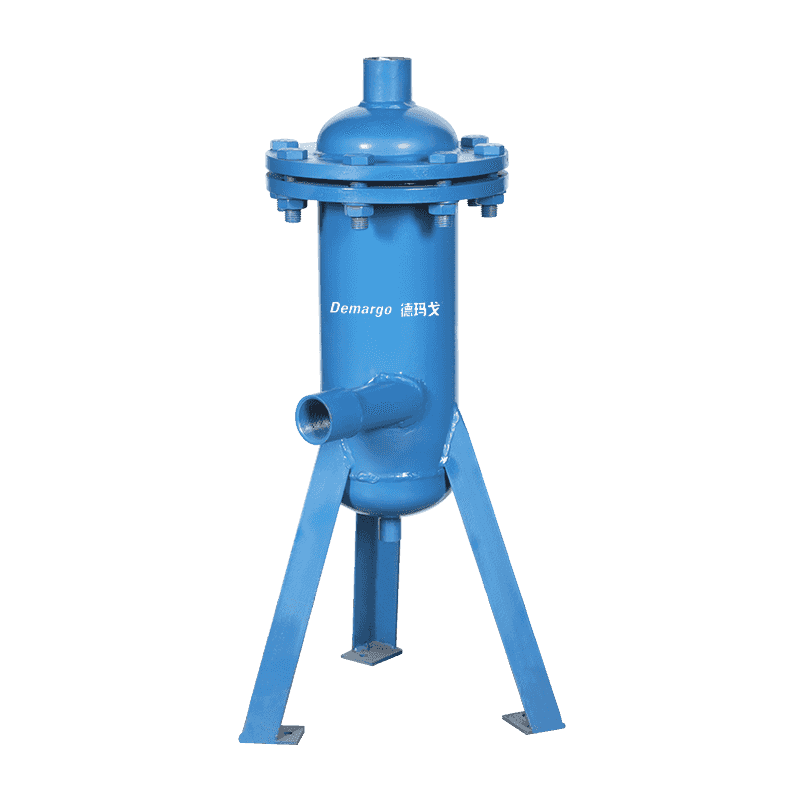

Microheat combined compressi aer dryer Venditores. Inter producta eius sunt siccatores refrigerati, siccatores adsorptionis, siccatores compositi, siccatores et filtra adsorptionis cum regeneratione caloris compressi, siccatores caloris flatus cum consumptione aeris nulla, filtra aeris auto-purganda, unitates prae-refrigerationis aeris compressi, unitates prae-refrigerationis nitrogenii temperaturae humilis et pressionis altae, refrigeratoria industrialia, separatores olei et aquae, removetores olei altae efficientiae, post-refrigeratores, et alia specificationes. Secundum necessitates usorum, apparatum purificationis aeris compressi variis generibus et proprietatibus praebere potest, ut refrigerationem aeris, refrigerationem aquae, refrigerationem normalem, refrigerationem sine fluoro, refrigerationem altam, refrigerationem instrumentalem, refrigerationem microcomputatralem unius fragmenti, refrigerationem programmabilem, refrigerationem industrialem, refrigerationem conversionis frequentiae, refrigerationem altae pressionis, refrigerationem contra explosiones, etc. Spatium puncti roris producti: -23°C ~-70Celsius, capacitas processus: 1~500Nm³/min, contentum olei exportationis: 10PPM~0.003PPM. Magnitudo particularum pulveris exportatae: 3um~0.01um.

Demargo (Shanghai) Energy Saving Technology Co., Ltd. Valde facultates habet in investigatione, designatione et evolutione productorum. Fundata in technologiarum provectarum digestione et absorptione domi et in terris externis, una cum condicionibus laboris actualibus in Sinis, apparatus purificationis aeris Demargo feliciter elaboratus optimus est apparatus filtrationis suctionis et purificationis post-processus pro variis compressoribus aeris sine oleo et sine oleo. Producta late adhibentur in energia electrica, constructione navali, aërospatio, electronicis, metallurgia, machinis, fabricatione autocinetorum, petroleo, industria chemica, textilibus, fibris chemicis, industria levi, charta, gummi, instrumentis, cibo, separatione aeris, cigarettis, medicina, biologia, chemicis quotidianis, aliisque industriis. Bene venduntur in plus quam XXX provinciis et urbibus per totam regionem et partes activas agunt in proiectis nationalibus maximi momenti. Producta exportata sunt in Brasiliam, Australiam, Iraniam, Indiam, Sudaniam, Indonesiam, Vietnam, Arabiam Sauditanam et alias partes Asiae Meridionalis Orientalis, Orientem Medium et Asiam Centralem, necnon Africam.

Societas "sincera dedicatione et excellentiae studio" ut spiritu suo communi utitur, et finem assequitur ut negotium per technologiam, qualitatem et servitium evolvat, cum designio productorum provecto, plena qualitatis cura et celeri reti servitii ante-venditionem et post-venditionem. Offerimus...

Microheat combined compressi aer dryer venale.